The forward reverse motor control

is used i a system where forward and backward or upward and downward movement

in the operation are needed.

An example of which are shown in

figures below (a) and (b). Figure below (a) shows forward and backward lateral

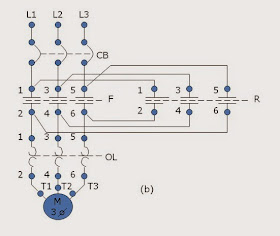

movement of an overhead crane driven by motor M. Figure below (b) shows a

downward and upward movement of a load is driven by motor lifter M.

(a) Lateral movement of an overhead crane driven by a motor.

(b) Vertical movement of a lift by a motor.

Control Operation

The

clockwise (forward) and counterclockwise (reverse) rotation of a motor can be

caused by interchanging the connection of any of the two of its three terminals.

Figures (c) and (d) below will show how this can be done.

Advertisement

Contractors

F and R are interlocked. It means that if the contacts (1-2, 3-4, 5-6) of

contractor R can not be closed. On the other hand if the contacts (1-2, 3-4,

5-6) of contractor R are closed, contacts (1-2, 3-4, 5-6) of contractor F can

not be closed.

Note

that when the contacts of contractor F in Figure (a) are closed, L1 is

connected to T1 through contact F (1-2), L2 is connected to T2 through contact

F(3-4), and L3 is connected to T3 through contact R(5-6).The motor M will run

forward.

When

the contacts of contractor R in the Figure (a) are closed, L1 is connected to

T3 through contact R (1-2), L2 is connected to T2 through contact R(3-4) and L3

is connected to T1 through contact R(5-6). The motor M will run reverse.

Referring

to the control circuit on Figure (a), pressing the forward push button F will

energize contactor F. Maintaining contact F (13 14) will close to maintain

contact or F continually energized even if the forward push button is release.

Contactor F (11-12) will open to prevent contactor R to be energized. Contacts

F(1-2, 3-4, 5-6) will close to run motor M on forward direction.

Pressing

the stop push button will de-energized contactor F. This will cause the

contacts R(1-2, 3-4, 5-6) to open and stops the motor M from running forward.

Contacts F(11-12) will close again. Maintaining contact F(13-14) will open.

Pressing

the reverse push button R will energize contactor R. Maintaining contact

R(13-14) will close to maintain contactor R continually energize evenif the

reverse push R button is release. Contacts R(11-12) will open to prevent

contactor F to be energized. Contacts R (1-2, 3-4, 5-6) will close to run motor

M on reverse direction.

Pressing

the stop push button again will de-energized contactor R. This will cause the

contacts R(1-2, 3-4, 5-6) to open and stops the motor from running reverse.

Contact R(11-12) will close again. Maintaining contact R(13-14) will open. This

brings the condition of the circuit the same as the one shown in Figures (a)

and (b) below.

(a) Control circuit of Forward – Reverse Motor Control with limit switches X and Y.

(c) Connection of Motor to power lines at forward condition.

Read Next Article:---> AUTO TRANSFORMER REDUCE VOLTAGE STARTER

Back to Previous Article:<--- WYE-DELTA REDUCE VOLTAGE STARTER

Video for Installing Led Lights:<--- Installing Mini Driving Light on KTM DUKE 200/390 - Dual Color - Best Cheap Fog/Auxiliary Led Light

Video for Installing Led Lights:<--- Installing Mini Driving Light on KTM DUKE 200/390 - Dual Color - Best Cheap Fog/Auxiliary Led Light

may i know the advantages and the disadvantages for the forward reverse starter?

ReplyDeleteGood Content Sir.. Well Done.. I also use Fluid-Sim to as Simulator.. I used it in installing Led Lights on my Motorcycle

ReplyDelete